FF and MIVOLT recently collaborated on “Going Further,” a live, joint webcast that took an in-depth look at EV battery technology using submerged cooling. Experts from both companies – including Nicolas Bel, Senior Lead Thermal Engineer at FF – explained the benefits of the FF submerged cooling system using MIVOLT fluids as a dielectric coolant.

“We are thrilled to have the opportunity to partner with MIVOLT, a proven global leader in immersion cooling fluids, including the automotive space,” said Bob Kruse, Senior Vice President, Product Execution and Vehicle Engineering at Faraday Future. “At FF, we are working with leading-edge technology partners to advance our technological innovations, and MIVOLT continues to build on a reputation for innovative products and superior technical knowledge.”

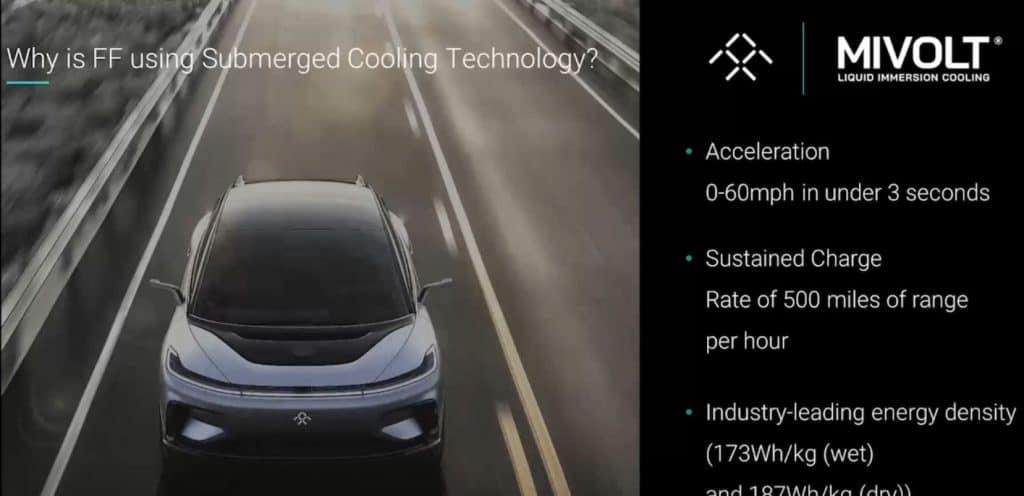

FF’s battery pack is a key system of its Variable Platform Architecture (VPA) that supports extraordinary vehicle capabilities such as ranges up to 378 miles and acceleration times as low as 0 to 60 mph in 2.39 seconds.* FF’s VPA also allows the FF 91 to fast charge at a rate of 500 miles of range per hour. These industry-changing numbers require a sophisticated system to deliver them safely and efficiently and such a system is directly tied to the thermal management of the battery pack.

FF explored numerous different cooling methods as the VPA was designed. After a wide-ranging evaluation, the FF team came up with a unique solution: a fully submerged system. In 2015, FF pioneered a patented cooling scheme where all major battery components are submerged in coolant.

The battery cells perform their best at temperatures near room temperature, and, as they release or store energy, they tend to get hot, so the cooling scheme becomes a crucial part to ensure top performance during the useful life of the vehicle. The coolant FF chose is a non-conductive liquid with excellent thermal properties that allows the pack to have uniform temperature across all its components. With the coolant surrounding every inch of cells, current collectors, and control units, we achieve stable temperatures between modules and strings, enabling the battery pack to better respond to the high demands of our vehicle.

The cooling system also eliminates potential risk of corrosion as all electrical components and their connections are submerged in the fluid. FF engineers reduced the spacing between cells and increased the total energy density of the pack, as the coolant can flow freely even at millimetric distances. Also, it provides a natural dampening effect relative to component vibration. The pack used in the FF 91 incorporates an innovative coolant flow design enabling each cell to be individually cooled.

FF continuously strives to incorporate new ideas to improve vehicle performance, reliability, safety, and user-focused features in FF’s overall design ideology.

From expressive aerodynamic exteriors to thoughtfully improved and driver-focused technologies, our talented engineers and designers embrace this vision and pursue exciting new approaches to remedy long-standing issues in the traditional automotive industry.

According to FF’s production launch plan, FF 91 will kick off production approximately nine months following the closing of a successful round of funding. The newly announced FF 81 EV and development preparation for future models and next generation core technologies will follow the introduction of FF 91.