Ford announced its connected car and financial future forecasts. It will embrace the technological changes and new competition the industry. To deliver, the company is expanding its scope to include vehicles and services – all designed around human-centered experiences. The company will tap its strengths integrating hardware and software in complex devices, its proven ability to deliver scale and the trust tied to the Ford brand. Meanwhile, Ford is helping to encourage youth by offering the Ford STEAM Experience to students.

Ford announced its connected car and financial future forecasts. It will embrace the technological changes and new competition the industry. To deliver, the company is expanding its scope to include vehicles and services – all designed around human-centered experiences. The company will tap its strengths integrating hardware and software in complex devices, its proven ability to deliver scale and the trust tied to the Ford brand. Meanwhile, Ford is helping to encourage youth by offering the Ford STEAM Experience to students.

Specifically, Ford is:

- Accelerating the introduction of connected, smart vehicles and services customers want and value. By 2019, 100 percent of Ford’s new U.S. vehicles will be built with connectivity. The company has similarly aggressive plans for China and other markets, as 90 percent of Ford’s new global vehicles will feature connectivity by 2020.

- Rapidly improving fitness to lower costs, release capital and finance growth. Ford is attacking costs, reducing automotive cost growth by 50 percent through 2022. As part of this, the company is targeting $10 billion in incremental material cost reductions. The team also is reducing engineering costs by $4 billion from planned levels over the next five years by increasing use of common parts across its full line of vehicles, reducing order complexity and building fewer prototypes.

- Allocating capital where Ford can win the future. This starts with the company reallocating $7 billion of capital from cars to SUVs and trucks, including the Ranger and EcoSport in North America and the all-new Bronco globally. Ford also has plans to build the next-generation Focus for North America in China, saving capital investment and ongoing costs. Further, Ford is reducing internal combustion engine capital expenditures by one-third and redeploying that capital into electrification – on top of the previously announced $4.5 billion investment.

- Embracing partnerships. Ford will continue to leverage partnerships, remain active in M&A and collaborate to accelerate R&D. The company recently announced it was exploring a strategic alliance with Mahindra Group as it transforms its business in India, and Zoyte with the intention of developing a new line of low-cost all-electric passenger vehicles in China. When it comes to autonomous vehicle development, the company recently announced a relationship with Lyft to work toward commercialization and a collaboration with Domino’s Pizza to research the customer experience of delivery services.

- Expanding electric vehicle revenue opportunities. The company recently announced a dedicated electrification team within Ford, focused exclusively on creating an ecosystem of products and services for electric vehicles and the unique opportunities they provide. This builds on Ford’s earlier commitment to deliver 13 new electric vehicles in the next five years, including F-150 Hybrid, Mustang Hybrid, Transit Custom plug-in hybrid, an autonomous vehicle hybrid, Ford Police Responder Hybrid Sedan, and a fully electric small SUV.

“When you’re a long-lived company that has had success over multiple decades the decision to change is not easy – culturally or operationally,” Hackett said. “Ultimately, though, we must accept the virtues that brought us success over the past century are really no guarantee of future success.”

Revamping product development, modernizing factories

At the same time, Ford is redesigning its operations to better compete in this disruptive era.

Hackett cites as a template the example of how the company re-imagined the all-new 2015 F-150. Since then, the F-Series has gained market share and the average transaction price has increased 16 percent. It has improved fuel economy and increased capability for customers, thanks in part to a 700-pound weight reduction that helped make the F-150 the company’s most positive contributor to CAFE standards for model year 2018. Additionally, 90 percent of the manufacturing equipment can be reused for the next-generation F-150, reducing future capital requirements. Finally, the innovation on aluminum and light weighting will pay off across a range of Ford trucks and SUVs.

Other priorities include:

- Reducing orderable combinations of many nameplates, focusing on what customers value most. Already the team has identified a ten-fold reduction of orderable combinations in the next-generation Escape and is moving from approximately 35,000 combinations in the current generation of Fusion to 96 in the next generation.

- Rethinking product development processes and incorporating new technology. In the next five years, Ford is aiming to reduce new vehicle development time by 20 percent, with new tools and fewer orderable combinations. Through the use of virtual assembly lines, the company has been able to reduce new model changeover time by 25 percent.

- Redesigning the company’s factories of the future. Accelerating and scaling 3D printing, robotics, virtual reality tools and big data will improve logistics and enable a more efficient manufacturing footprint.

“We believe Ford will achieve its competitive advantage by focusing deeply on our customers – whether they’re drivers, riders or cities – and that’s where we are playing to win,” Hackett said.

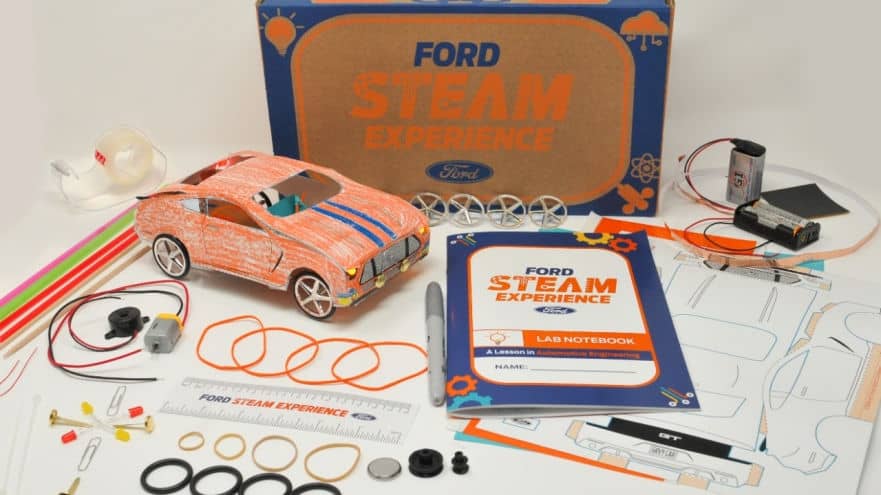

To help spur youth to become engineers Ford is bringing science, technology, engineering, the arts, and math (STEAM) education to youth across the country with fun, and educational challenges delivered right to their doorsteps.

Ford launched fordsteamexperience.com as a way to showcase many of the education-focused programs it offers. The company’s newest one is a collaboration with Academics in a Box, designers of Groovy Lab in a Box, an award-winning educational kit line designed for children ages 8 and up interested in learning STEAM fields. The unique experience is delivered right to their homes at no cost when they sign up.

The Ford STEAM Box challenges youth to think like a Ford engineer. The box includes a number of activities – designing a vehicle frame out of origami and kirigami modeling, working with copper tape which conducts electricity to create a working motor, and creating headlights and taillights using LED lighting – all adding up to a complete prototype of a Ford Mustang GT model.