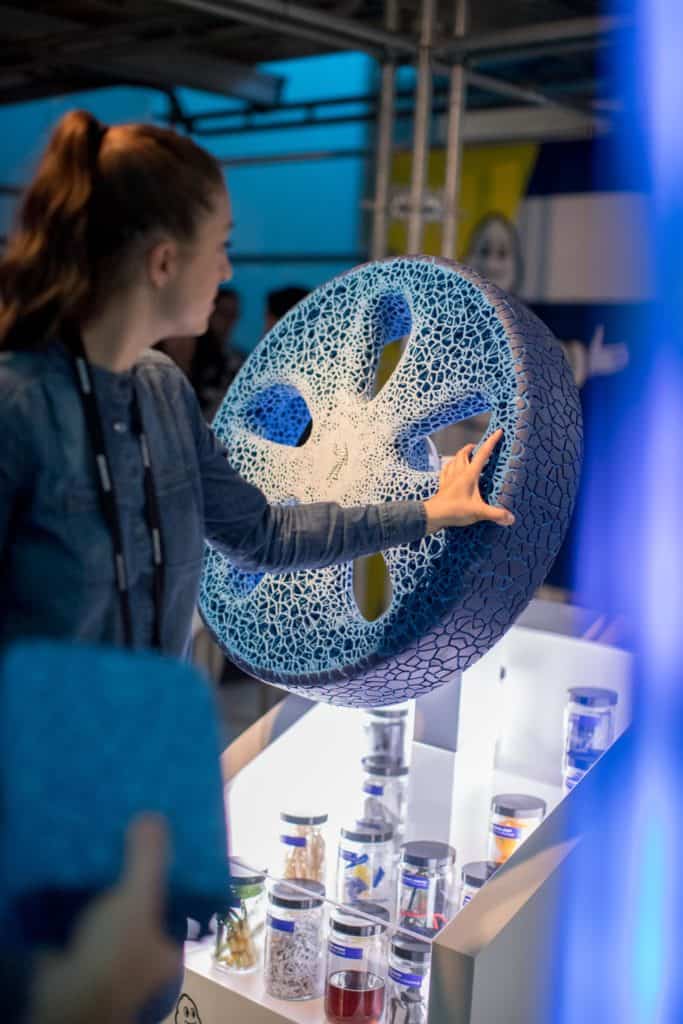

Michelin premired VISION, its concept tire, which is a concentration of technologies at Movin’On 2017 in Montreal, Canada. This concept tire, which is airless, connected, rechargeable, customizable and organic, is both a wheel and a tire. It looks like coral but works like a smartphone.

Michelin premired VISION, its concept tire, which is a concentration of technologies at Movin’On 2017 in Montreal, Canada. This concept tire, which is airless, connected, rechargeable, customizable and organic, is both a wheel and a tire. It looks like coral but works like a smartphone.

By offering a mobility solution that combines a unique tire, services and materials, Michelin is unveiling an innovation that is inspired by nature, is perfectly integrated into the framework of a circular economy an embodies the Group’s vision of the sustainable mobility of the future.

It was under the leadership of the Michelin Corporate Innovation Board (CIB) that the VISION project was launched in Autumn 2016. The CIB’s road map was simple: imagine an object that symbolized the mobility of the future, that was packed with converging technologies and offered an ultra-high level of environmental performance, in accordance with the Group’s 4R strategy and Michelin’s values.

Michelin began by listening to people, from city motorists to race drivers, from farmers to airline pilots, from engineering equipment drivers to children barely old enough to ride bikes. Some 90 people, divided into four panels around the world were questioned about their relationship with mobility. From these discussions, important needs were identified, in particular concerning sustainability. No users wanted to reduce their need for safety. Grip in all weather conditions and effective braking in all circumstances were essential. In addition, users embraced environmental responsibility. They wanted to consume cleanly. Why choose between a fully biodegradable tire and a rechargeable tire? Jean-Dominique SENARD and the members of the Corporate Innovation Board said: “Give us both”.

An organic tire

The materials used, which were both bio-sourced and biodegradable, minimized the tire’s environmental footprint.

A 3D printed tire

VISION is the world’s first tire that recharges. With the aid of 3D printers, it is possible to use just the right amount of rubber on the tire and thus extend its life depending on needs, thereby ensuring mobility in all situations. The tread design is optimized and its depth is reduced in order to reduce its thickness and make the tire more efficient in terms of materials. The tread

VISION is the world’s first tire that recharges. With the aid of 3D printers, it is possible to use just the right amount of rubber on the tire and thus extend its life depending on needs, thereby ensuring mobility in all situations. The tread design is optimized and its depth is reduced in order to reduce its thickness and make the tire more efficient in terms of materials. The tread

design is adapted, in accordance with the user’s mobility needs, with a triple concern for comfort, safety and sustainability.

An airless tire

VISION does away with air, relying instead on an interior architecture capable of supporting the vehicle, ensuring the solidity of the wheel and thus guaranteeing both comfort and safety. VISION can neither explode nor blowout.

A connected tire

Equipped with sensors, VISION provides real time information about its condition. What’s more, thanks to Michelin’s mobile application, it’s possible to simply make an appointment to change the tire’s destination, depending on the user’s needs.