To satisfy the demand for internet of things (IoT) and mobility applications Bosch will build a new factory to manufacture chips based on 12-inch wafers. Construction of the high-tech plant is to be completed by the end of 2019. Following a rollout phase, manufacturing operations will likely start at the end of 2021. Total investment in the location will come to roughly one billion euros. It is the single biggest investment in the 130-year history of Bosch.

To satisfy the demand for internet of things (IoT) and mobility applications Bosch will build a new factory to manufacture chips based on 12-inch wafers. Construction of the high-tech plant is to be completed by the end of 2019. Following a rollout phase, manufacturing operations will likely start at the end of 2021. Total investment in the location will come to roughly one billion euros. It is the single biggest investment in the 130-year history of Bosch.

Dresden’s microelectronics cluster, also known as “Silicon Saxony,” is unrivaled in Europe. It includes automotive suppliers and service providers, as well as universities offering technological expertise. In addition, the Digital Hub Initiative launched by the BMWi aims to make Dresden an IoT ecosystem. Bosch intends to collaborate closely with local companies, and in this way to reinforce not only Germany’s, but also Europe’s position as an industrial location.

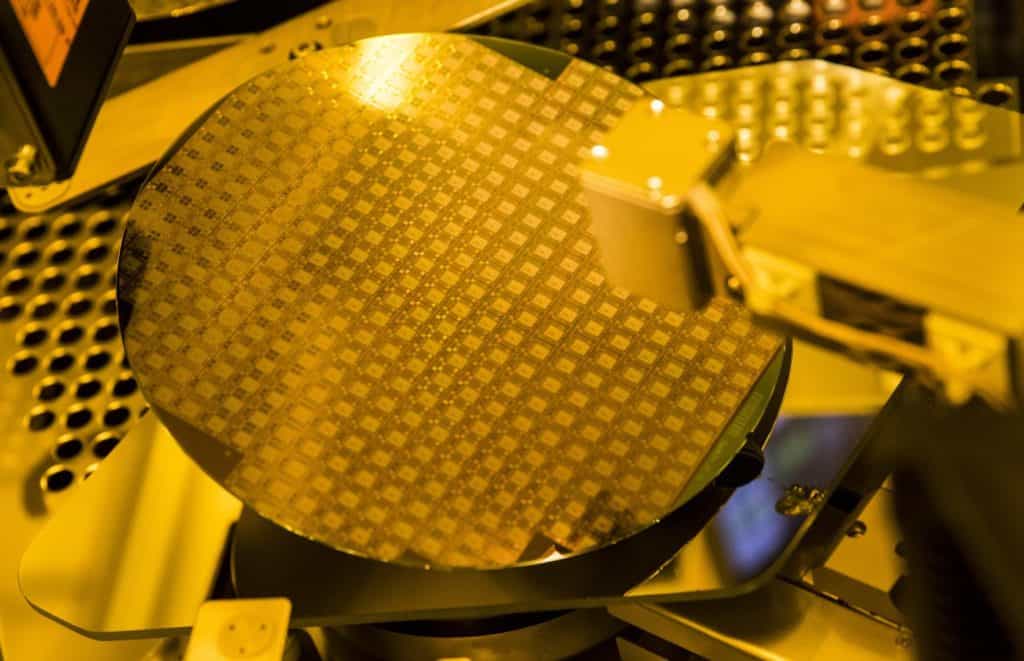

Semiconductors are a key technology for mobility, and connected, electrified, and automated homes. The process of manufacturing semiconductor chips always starts with a silicon disc, known as a wafer. The bigger their diameter, the more chips that can be made per manufacturing cycle. Compared with conventional 6- and 8-inch wafer fabs, 12-inch wafer technology offers economies of scale.

For more than 45 years, Bosch has been making semiconductor chips in multiple variants, above all as application-specific integrated circuits (ASICs), power semiconductors, and micro-electro-mechanical systems (MEMS). Bosch ASICs have been used in vehicles since 1970. They are customized to individual applications, and essential for functions such as airbag deployment. In 2016, every car rolling off the production lines worldwide had on average more than nine Bosch chips on board.

When it comes to MEMS sensors, Bosch is both a pioneer and the world’s leading manufacturer. More than 20 years ago, the supplier of technology and services itself developed the microfabrication technique known worldwide as the “Bosch process,” which is also used to make semiconductors. At its wafer fab in Reutlingen, Germany, Bosch currently manufactures some 1.5 million ASICs and 4 million MEMS sensors a day on the basis of 6- and 8-inch technology. All in all, the company has made more than 8 billion MEMS sensors since 1995. Today, 75 percent of Bosch MEMS sensors are used in consumer and communications electronics applications. Bosch MEMS sensors can be found in three out of four smartphones. Its current semiconductor portfolio includes above all acceleration, yaw, mass-flow, pressure, and environmental sensors, as well as microphones, power semiconductors, and ASICs for vehicle ECUs.