Bosch announced new battery technology, called solid-state cells for electric cars that could be production-ready in as little as five years. The technology could double energy density by 2020.

Bosch announced new battery technology, called solid-state cells for electric cars that could be production-ready in as little as five years. The technology could double energy density by 2020.

Bosch has invested heavily in the technology and reports that the acquisition of the Seeo Inc. will help make this possible.

Bosch now has crucial know-how in innovative solid-state cells for lithium batteries as well as exclusive patents.

Up to now, the declared industry target has been to double batteries’ energy density and halve their costs by the end of this decade. With the new solid-state cells, Bosch sees the potential to more than double energy density by 2020, and at the same time reduce the costs considerably further. A comparable electric car that has a driving range today of 150 kilometers would be able to travel more than 300 kilometers without recharging – and at a lower cost.

The acquisition of Seeo Inc. fits seamlessly into Bosch’s electromobility strategy. Bosch already offers a wide range of components for electromobility, from motors and power electronics to batteries. So far, Bosch has realized 30 production projects related to electromobility.

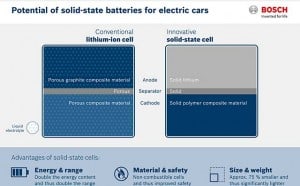

The performance of an energy storage device can be improved with various methods. For example, in cell chemistry, the material that the positive and negative poles (cathode and anode) are made of plays a major role.

In current lithium-ion batteries, one of the reasons energy capacity is limited is because the anode consists to a large degree of graphite. Using solid-state technology, Bosch can manufacture the anode out of pure lithium, which considerably increases storage capacity.

In addition, the new cells function without ionic liquid, which means they are not flammable.

Thanks to its acquisition of Seeo Inc., Bosch now possesses the first sample cells which have the potential to meet the high standards of the automotive industry where durability and safety are concerned.